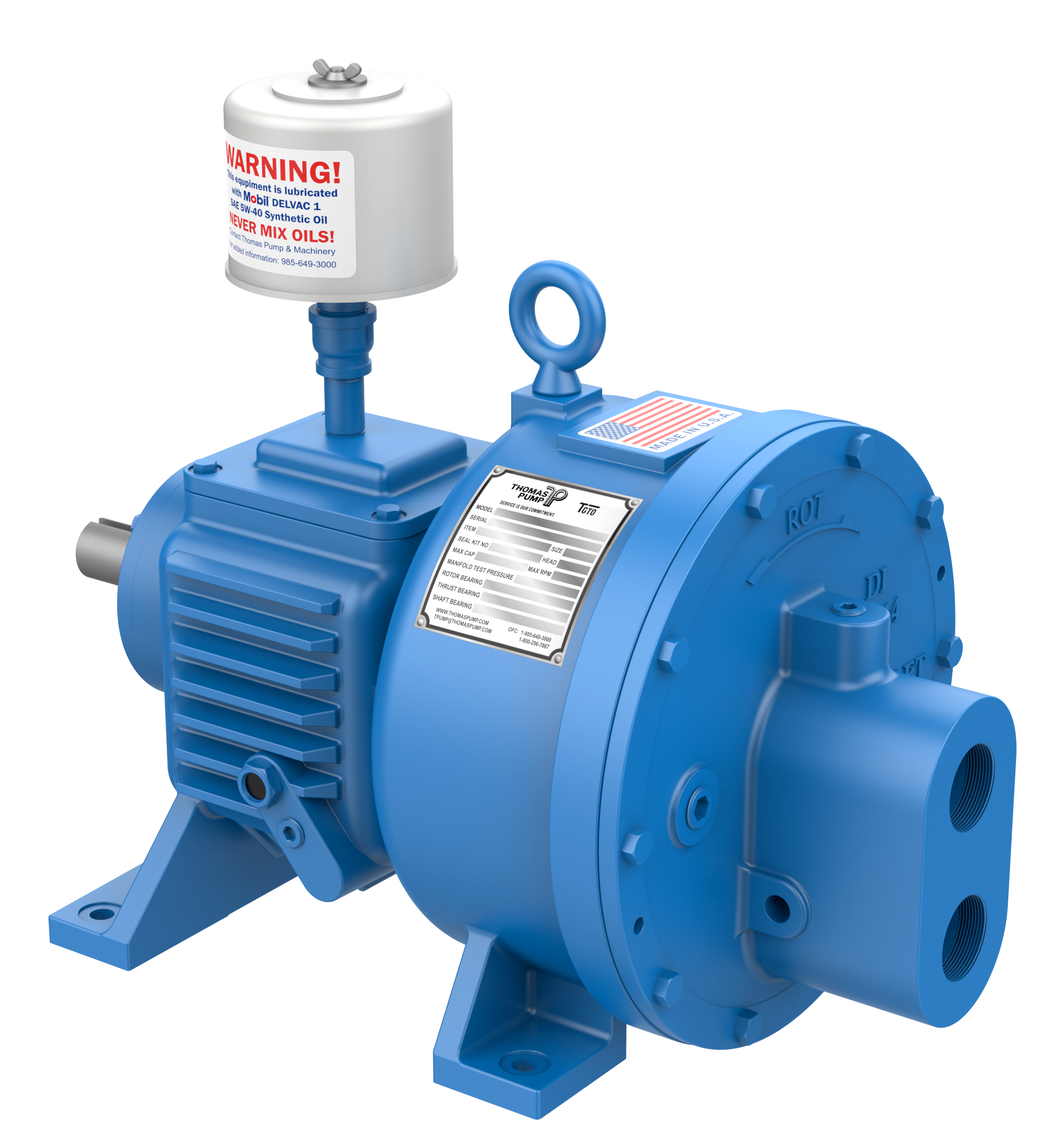

T-GTO Pump Features

- T-GTO Pump Pressure Range: 400-1200 PSI

- Oil LUBRICATED POWER FRAME WITH HIGHER CAPACITY AND SPEED

- Pitot tube allows for a wider operating range ( flow and pressure ) than traditional centrifugal or positive displacement pumps

- Pitot tube design produces a stable, pulsation free flow

T-GTO Pump Details

Max Capacity

400 GPM

Max Head

2625 FT

Max Pump Speed

4800 RPM

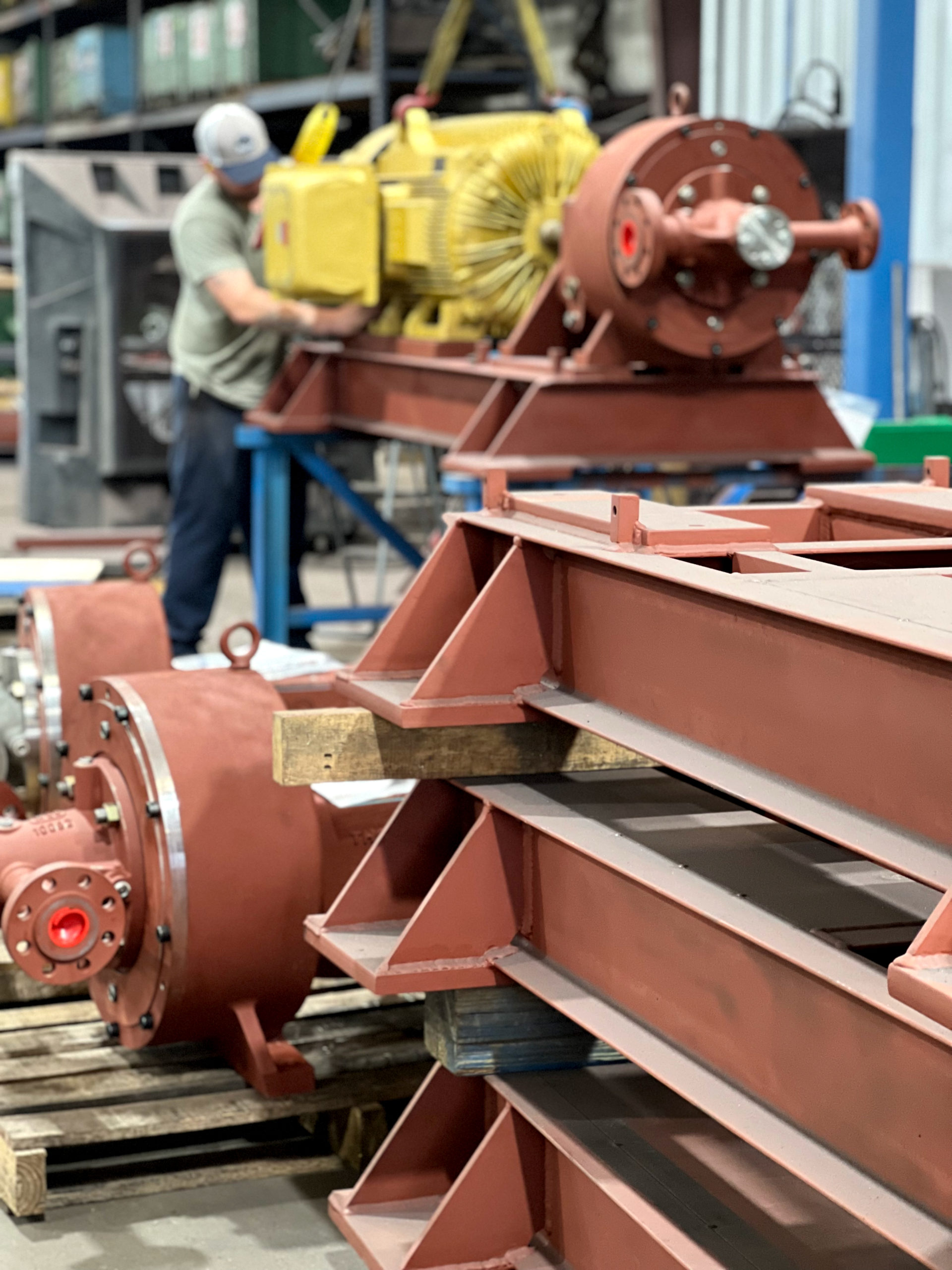

Backed by our 24/7 XChange program